1J27 is a Fe-Co-Cr soft magnetic alloy featuring exceptional ductility and toughness, ranking among the most formable materials in the family of high-saturation magnetic induction and high-Curie-temperature Fe-Co based soft magnetic alloys.

Its saturation magnetic induction is nearly equivalent to that of 1J22, while offering significantly better mechanical strength and toughness, thus avoiding the brittleness and cracking tendency often seen in 1J22.

1J27 is ideal for applications that demand a combination of high magnetic saturation, excellent ductility, and superior toughness.

Key Properties & Advantages

High saturation magnetic induction (comparable to 1J22)

High curie temperature, suitable for high-temperature magnetic environments

Excellent ductility and impact resistance for demanding applications

Low magnetic loss and stable magnetic performance

Good processability, suitable for both cold and hot forming

Typical Applications

Cores and rotors for high-speed electric motors

Generators and electromagnetic actuators

Aerospace and aviation magnetic systems

Precision magnetic components requiring both high saturation and toughness

Mechanical Properties (Strip Example)

Tensile strength Rm ≤ 570MPa

Yield strength Rel0.2 ≤ 400MPa

Elongation A ≥ 18%

Vickers Hardness ≤ 180HV

Supply Forms

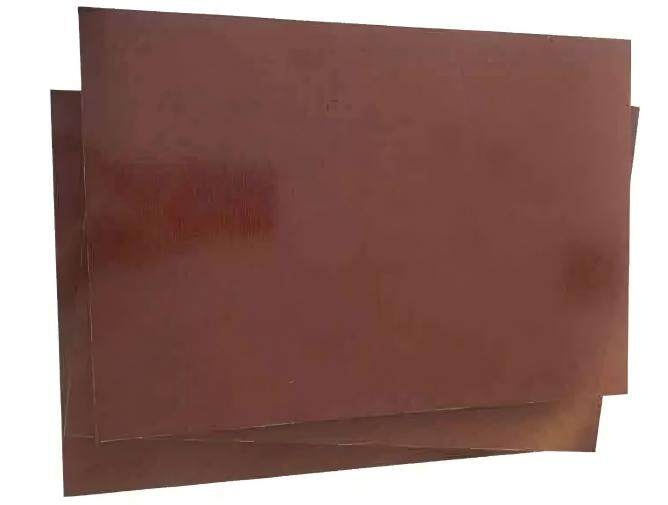

Specification: strip, sheet, and bar

Condition: cold-rolled, annealed

Customization: available upon request

Standards: specifications available according to Russian, American, British, French, and Japanese standards

- +86 15802938984

- shanghaiwtinternational@gmail.com