Copper Alloys – Versatile Materials for Precision and Performance

Key Material Advantages

Exceptional Electrical and Thermal Conductivity: Ideal for power transmission, heat exchangers, and electronic components.

High Corrosion Resistance: Performs well in marine, industrial, and chemical environments; resists tarnishing and degradation.

Superior Machinability and Formability: Easily forged, extruded, or machined into complex shapes with high dimensional accuracy.

Antimicrobial Properties: Naturally inhibits bacterial growth, making it suitable for sanitary and medical applications.

Good Strength and Wear Resistance: Select copper alloys (e.g., bronze and beryllium copper) offer high fatigue resistance and excellent mechanical durability.

Common Grades

Brass (Copper-Zinc Alloys): H62, H65, C26000 – Cost-effective, good corrosion resistance, widely used in mechanical parts, plumbing, and decorative applications.

Bronze (Copper-Tin and Copper-Aluminum Alloys): QSn6.5-0.1, C95400 – Renowned for strength, wear resistance, and long service life in heavy-duty components.

Beryllium Copper: C17200, QBe2.0 – Exceptional hardness, high strength, excellent conductivity; widely applied in aerospace, tools, and electronics.

High-Conductivity Copper: T1, C11000 – Superior electrical conductivity, essential for power cables, conductors, and electronic devices.

Cu-Ni Alloys (Copper-Nickel): BFe10-1-1, C70600 – Excellent resistance to seawater corrosion, widely used in marine equipment, condensers, and desalination systems.

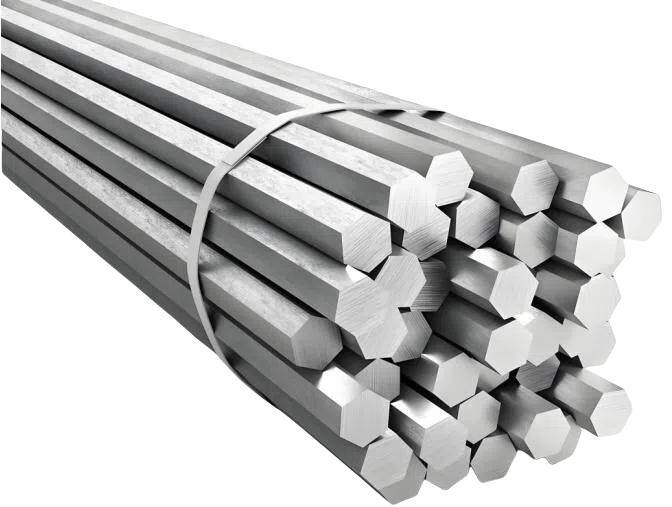

Product Forms Available

Bars, Plates, Pipes, Strips

Forgings: Rings, shafts, discs, customized shapes

Custom Machined Parts: According to drawings and specifications

Heat Treatment & Surface Finishing: Anodizing, sandblasting, precision polishing, coating, and other treatments

Applications

Electronics: Connectors, terminals, lead frames, conductive springs

Automotive & Transportation: Radiators, brake systems, bearings, bushings

Marine Engineering: Pumps, valves, propellers, seawater piping

Industrial Machinery: Gears, springs, seals, wear-resistant parts, friction-resistant components

Architecture & Construction: Roofing, cladding, decorative elements

Medical & Sanitary Systems: Antimicrobial surfaces, water supply components

Why Choose Us

Support for both small-batch customization and bulk supply

Full-process services including forging, machining, and heat treatment

Drawing-based production with support for third-party inspection and certification

Fast export handling with full support for international logistics and customs clearance

Contact us for tailored solutions and competitive offers!

- +86 15802938984

- shanghaiwtinternational@gmail.com