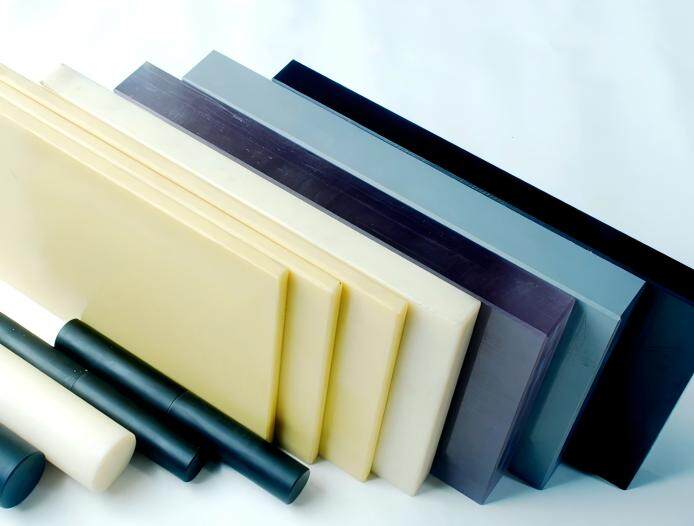

Product Forms and Customization

Epoxy Fiberglass Sheets

Thickness Range: 0.3mm-100mm

Standard Sizes: 1020×1220mm (customizable upon request)

Applications: electrical insulation boards, printed circuit board (PCB) base sheets, transformer insulation sheets, battery packaging boards

Epoxy Fiberglass Rods

Diameters: 6mm-200mm (custom sizes available)

Machining Options: cutting, drilling, slotting, end-face processing

Applications: insulation fasteners, insulating shafts, structural reinforcement parts

Epoxy Fiberglass Tubes

Manufactured by winding or molding processes

Customizable: tube diameter, wall thickness, and length

Applications: insulating sleeves, transformer insulation components, protective housings for electrical equipment

Product Advantages

High Strength and Durability: excellent tensile, compressive, and bending properties

Superior Electrical Insulation: stable dielectric performance, arc resistance, and leakage resistance

Heat Resistance (Class F): continuous operating temperature up to 155℃

Flame Retardancy (FR4): enhanced fire resistance for PCB and high-voltage applications

Moisture and Chemical Resistance: reliable under humid and corrosive environments

Versatile Customization: adjustable size, thickness, and machining options

Applications

Electrical Insulation: transformers, motors, switchgear, and electrical cabinets

Electronics Industry: PCB base sheets, insulation glass epoxy boards, electrical insulator laminated sheets

Energy & Power Systems: generator insulation boards, battery pack epoxy sheets, wind power insulation components

Mechanical & Industrial Structures: structural insulating connectors, mold base plates, support parts requiring high strength and insulation

- +86 15802938984

- shanghaiwtinternational@gmail.com