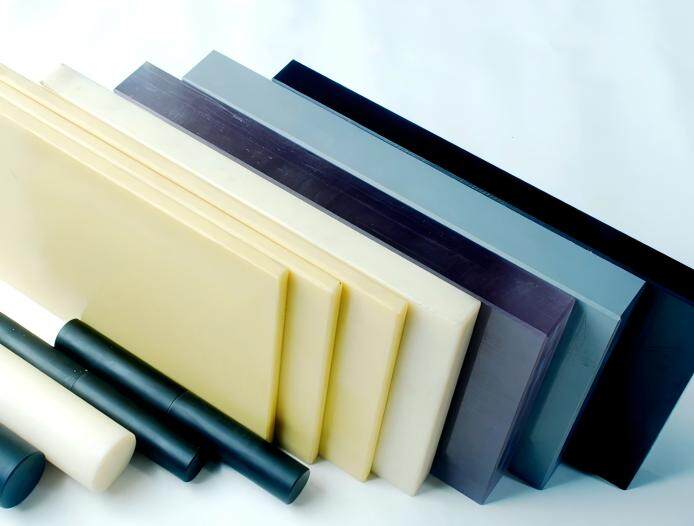

Product Forms and Customization

Vacuum Insulation Panels (VIP Sheets)

Thickness: 5mm-50mm

Standard Sizes: 300×600mm, 600×1200mm (custom sizes available: extended width and length)

Secondary Processing: cutting, slotting, precision shaping

Applications: building insulation, energy-efficient construction, appliance insulation, cold chain logistics

Vacuum Insulation Rods (VIP Rods)

Diameter: a few millimeters to several centimeters (customizable)

Length: adjustable according to customer requirements

Applications: high-voltage electrical insulation supports, thermal isolation columns for precision instruments, industrial pipeline supports

Vacuum Insulation Tubes (VIP Tubes)

Customizable inner diameter, outer diameter, and length

Applications: vacuum insulated pipelines, cylindrical insulation for cold chain transport, protective sleeves for equipment

Product Advantages

Ultra-Low Thermal Conductivity: ≤0.004 W/(m·K), significantly lower than traditional insulation materials

Space-Saving Design: thinner structure with equal insulation performance, improving space utilization

Long-Term Stability: vacuum retention for 10-30 years with high-performance barrier film

Eco-Friendly & Energy-Saving: made of green materials, free from CFCs and other harmful substances

Flexible Customization: available in extended, widened, thickened, or custom-shaped designs

Applications

Building Energy Efficiency: exterior walls, roofs, and flooring insulation

Cold Chain Logistics: refrigerated containers, transport equipment, thermal storage boxes

Home Appliances: refrigerators, freezers, water heaters, and smart appliances

Industrial & Transportation: insulation sleeves for high-end equipment, rail transit, and aerospace applications

Scientific & Precision Instruments: high-voltage insulation, thermal control systems, and laboratory equipment

- +86 15802938984

- shanghaiwtinternational@gmail.com