1J21 is a high-performance soft magnetic alloy with the highest saturation magnetic induction (up to 2.4T) and low iron loss, representing the top tier in soft magnetic materials. Its key feature is delivering extremely high magnetic induction while maintaining low energy loss.

Key Properties & Advantages

High Saturation Magnetic Induction (2.4T): enables higher magnetic flux density.

Low Core Loss: improves motor and generator efficiency while reducing energy loss.

High Power Density & Efficiency: supports maximum torque density and compact motor design.

Wide Applications: excellent performance in electrical, medical, and other specialized fields.

Typical Applications

Motor and generator cores — improve power density and efficiency

Electromagnetic poles — medical radiology equipment

Specialized transformers

Magnetic bearings

Actuators and magnetic components

Mechanical Properties (Hardened, Rod Example)

Tensile strength Rm ≈ 260MPa

Yield strength Rp0.2 ≈ 185MPa

Elongation A ≈ 0.66%

Machinability

In the hardened state, 1J21 exhibits high brittleness and low ductility, making it prone to chipping and edge breakage during machining. Advanced machining techniques, proper tooling materials, and optimized cutting parameters are required.

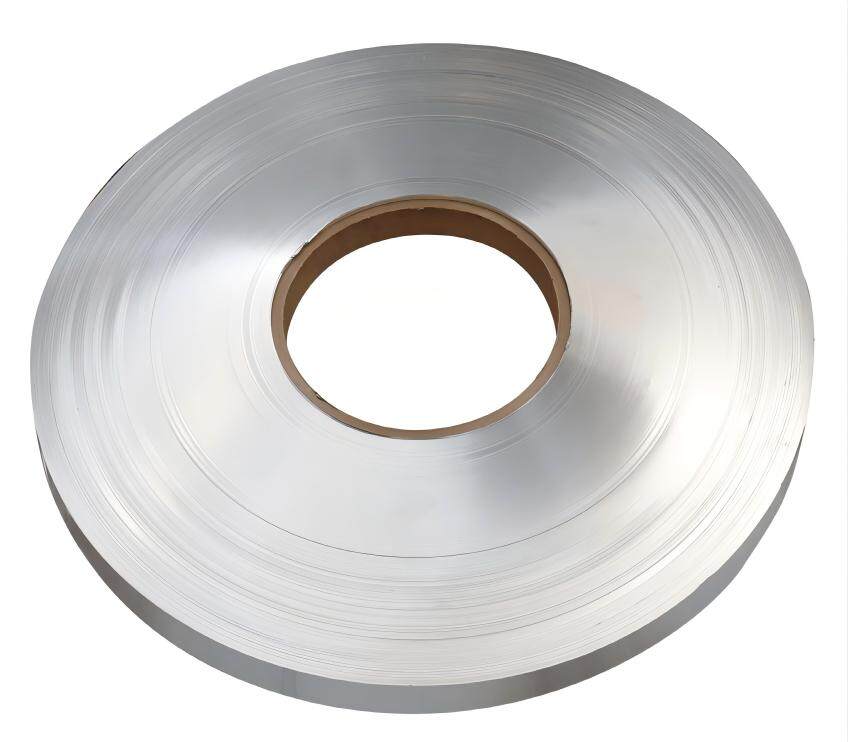

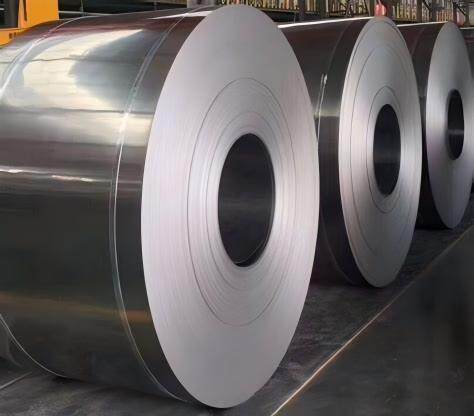

Supply Forms

Specifications: rod, plate, strip, wire

Conditions: cold-rolled, annealed

Customization:tailor-made processing available upon request

- +86 15802938984

- shanghaiwtinternational@gmail.com