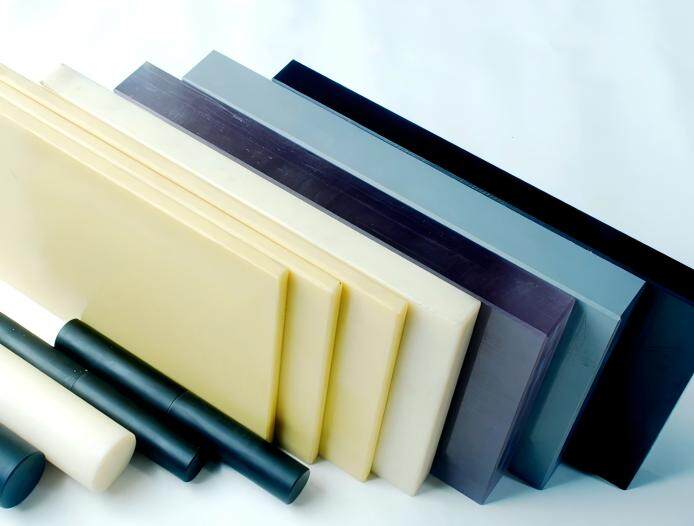

Product Forms and Customization

3026 Phenolic Resin Board

Thickness range: 0.5mm-50mm

Standard size: 1020×1220mm, customizable width, length, and thickness

Secondary processing: Cutting, slotting, drilling

Applications: Electrical insulation components, mechanical structural parts, mold bases

3026 Phenolic Resin Rod

Standard diameters: 6mm-150mm

Custom lengths and precision diameters available

Applications: Insulation shafts, support components, fasteners

3026 Phenolic Resin Tube

Customizable inner/outer diameters and lengths

Manufactured via winding or molding processes

Applications: Insulation sleeves, mechanical structural parts, electrical equipment housings

Product Advantages

High Heat Resistance: Continuous working temperature up to 160℃

Flame Retardant: Self-extinguishing, compliant with IEC/UL standards

High Mechanical Strength: Excellent tensile, compressive, and bending resistance

Chemical Resistance: Suitable for humid, mildly acidic, and alkaline environments

Flexible Customization: Supports extended, widened, or thickened dimensions and various secondary machining processes

Applications

Electrical Insulation: Motors, transformers, switchgear, relays

Mechanical Structure: Support components, mold bases, fasteners

Industrial Equipment: Instruments, electrical control cabinets, heat-resistant panels

Transportation & Energy: Rail transit, power equipment, wind power applications

- +86 15802938984

- shanghaiwtinternational@gmail.com