Nickel Alloys & Iron-Nickel Alloys – High-Performance Metals for Extreme Environments

Key Material Advantages

High-Temperature Strength: Nickel-based alloys maintain structural integrity under extreme heat.

Low Thermal Expansion: Iron-nickel alloys ensure precision and dimensional stability.

Corrosion & Oxidation Resistance: Reliable performance in chemical, marine, and industrial environments.

Durable Mechanical Properties: Long-lasting under stress, fatigue, and vibration.

Customizable Designs: Supports special geometries, surface treatments, and alloy grades.

Common Grades

Nickel Alloys:

Inconel Series: Inconel 600, 625, 718–High-temperature and corrosion-resistant superalloys for aerospace and energy industries

Hastelloy Series: Hastelloy C-22, C-276–Excellent chemical resistance for industrial and marine applications

Monel Alloys: Monel 400, K500–Corrosion-resistant alloys suitable for marine and acidic environments

Pure Nickel Grades: Nickel 200, 201–High electrical and thermal conductivity for electronics and industrial components

Iron-Nickel Alloys:

Invar (36% Ni): Low thermal expansion for precision instruments, optical devices, and aerospace structures

Kovar (29% Ni, 17% Co): Matched thermal expansion for glass-to-metal sealing in electronics and semiconductors

Alloy 42: Controlled expansion for industrial electronics and precision assemblies

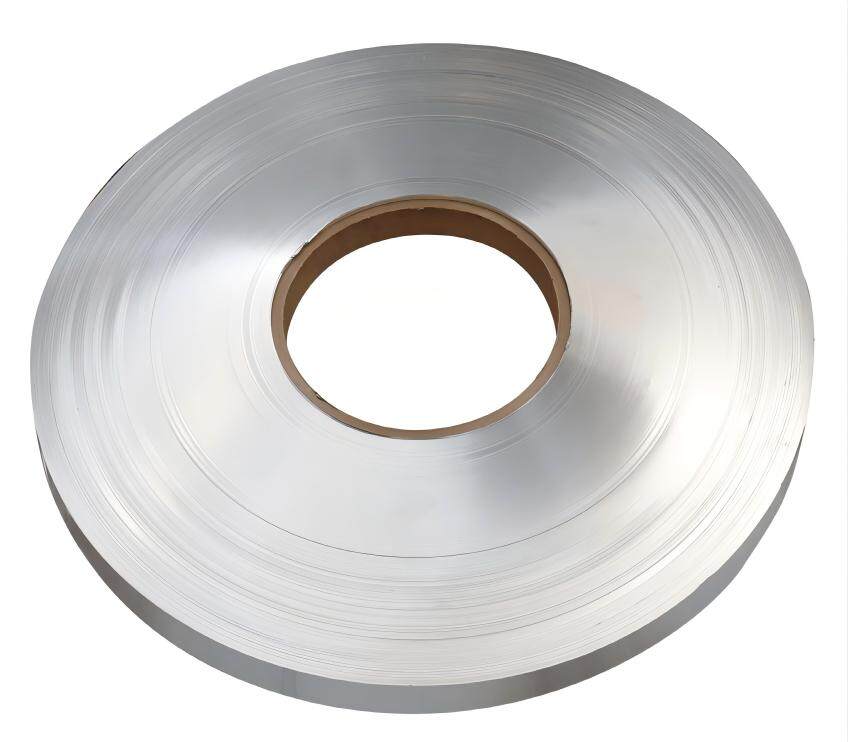

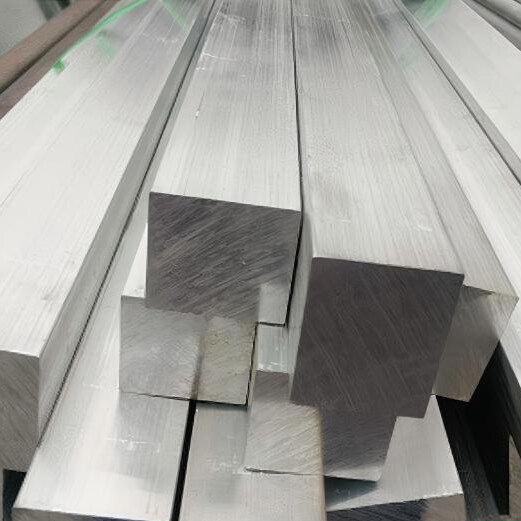

Product Forms Available

Bars, Plates, Pipes, Strips

Forgings: Rings, shafts, discs, customized shapes

Custom Machined Parts: According to drawings and specifications

Heat Treatment & Surface Finishing: Anodizing, sandblasting, precision polishing, coating, and other treatments

Applications

Aerospace & Aviation: Turbine components, engine parts, structural assemblies

Chemical & Marine: Reactors, piping, pumps, seawater-resistant components

Electronics: Vacuum tubes, semiconductor packages, sensor parts

Power Generation & Energy: Boilers, heat exchangers, and industrial processing equipment

Precision Machinery: Measurement instruments, semiconductor packaging, satellite components

Why Choose Us

Support for both small-batch customization and bulk supply

Full-process services including forging, machining, and heat treatment

Drawing-based production with support for third-party inspection and certification

Fast export handling with full support for international logistics and customs clearance

Contact us for tailored solutions and competitive offers!