Superalloys – Heat Resistant High Strength Materials for Extreme Environments

Key Material Advantages

Excellent High-Temperature Strength: Retains mechanical integrity and creep resistance at temperatures exceeding 700°C, ideal for turbine, aerospace, and power generation components.

Outstanding Oxidation and Corrosion Resistance: Forms stable protective oxide layers in extreme thermal, chemical, and marine environments, ensuring long-term performance.

Long Service Life: Engineered for thermal fatigue resistance and structural stability during prolonged high-temperature exposure.

Superior Structural Reliability: Minimal deformation or degradation under cyclical, high-stress, or high-pressure operating conditions.

Process Adaptability: Compatible with casting, forging, welding, and complex precision machining, enabling reliable manufacturing of critical components.

Common Alloy Series

Nickel-Based Superalloys / High Temperature Alloys:

Inconel 625, Inconel 718 – High-temperature, corrosion-resistant alloys for aerospace and energy industries

Hastelloy C-22 – Excellent chemical resistance for industrial and marine applications

Waspaloy – High-strength alloy for extreme temperature components

Iron-Nickel-Based High Temperature Alloys:

Incoloy 800, Incoloy 825 – Resistant to oxidation and chemical attack in industrial processes

Cobalt-Based Superalloys / High Temperature Alloys:

Haynes 188, Stellite 6 – High wear resistance, temperature strength, and chemical stability

Product Forms Available

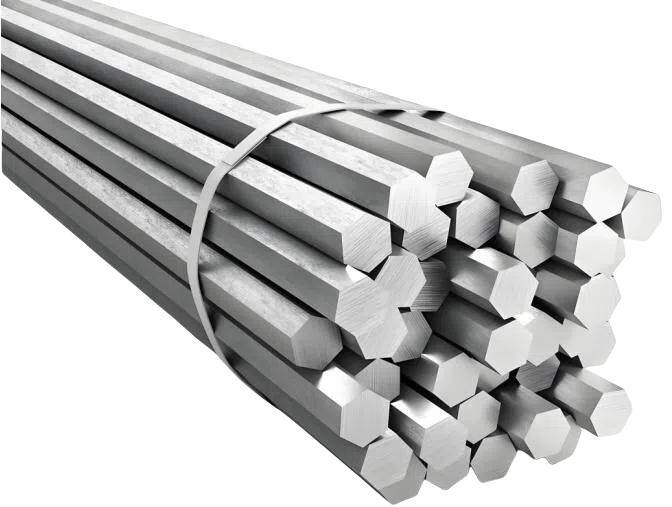

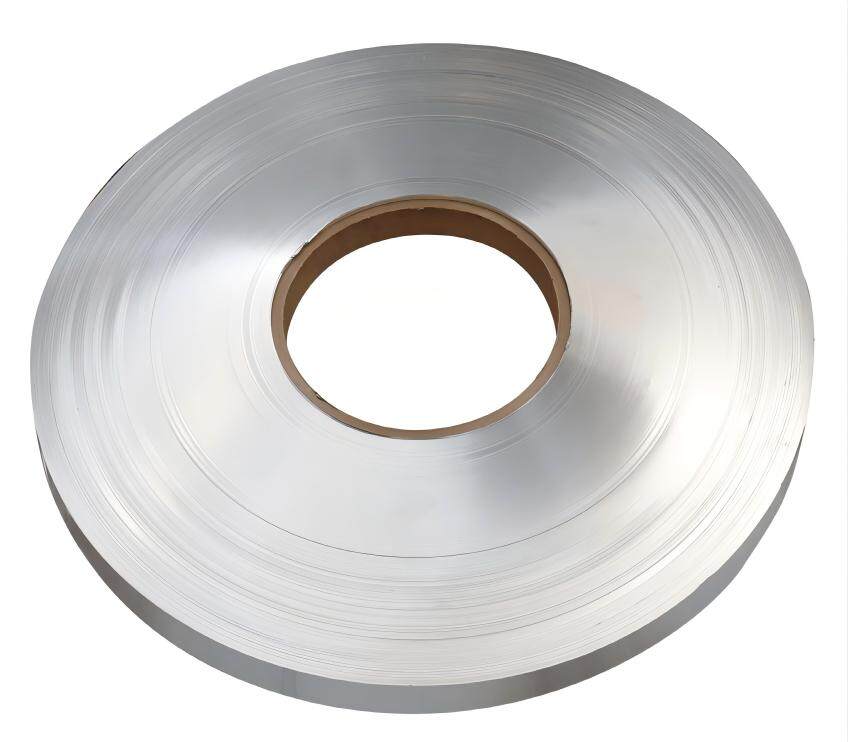

Bars, Plates, Pipes, Strips

Forgings: Rings, shafts, discs, customized shapes

Custom Machined Parts: According to drawings and specifications

Heat Treatment & Surface Finishing: Anodizing, sandblasting, precision polishing, coating, and other treatments

Applications

Aerospace & Aviation: Turbine blades, engine components, structural assemblies

Power Generation: Gas turbines, steam turbines, heat exchangers

Chemical Processing: Acid-resistant vessels, pumps, heat-resistant fasteners

Marine Engineering: High-temperature valves, propulsion components

Metal Processing: Furnace parts, crucibles, high-temp tooling fixtures

Why Choose Us

Support for both small-batch customization and bulk supply

Full-process services including forging, machining, and heat treatment

Drawing-based production with support for third-party inspection and certification

Fast export handling with full support for international logistics and customs clearance

Contact us for tailored solutions and competitive offers!

- +86 15802938984

- shanghaiwtinternational@gmail.com