Titanium Alloys – High-Performance Metals for Demanding Applications Description

Key Material Advantages

High Strength-to-Weight Ratio: Delivers strength comparable to steel while being significantly lighter, enabling weight reduction, improved fuel efficiency, and optimized structural design.

Excellent Corrosion Resistance: Provides superior resistance in acidic, alkaline, marine, and high-temperature gas environments, ensuring long service life.

Thermal Stability: Retains mechanical properties during long-term exposure to elevated temperatures, widely applied in jet engines, turbines, and other high-heat equipment.

Superior Biocompatibility: Non-toxic, non-allergenic, and non-magnetic, making titanium alloys the preferred material for surgical implants, dental devices, and medical instruments.

Excellent Weldability and Machinability: Ideal for forging, turning, milling, precision machining, and custom component manufacturing.

Common Grades

Commercially Pure Titanium: TA1, TA2, Grade 1, Grade 2 – Excellent corrosion resistance, good ductility, widely used in chemical processing and medical applications.

General-Purpose Titanium Alloys: TC4 (Ti-6Al-4V), Ti-3Al-2.5V – High strength, corrosion resistance, and processability, the most commonly used engineering grades.

High-Temperature Titanium Alloys: Ti-6Al-2Sn-4Zr-6Mo, Ti-6242, Ti-5553 – Designed for long-term service at elevated temperatures with superior creep resistance, applied in aerospace engines and gas turbines.

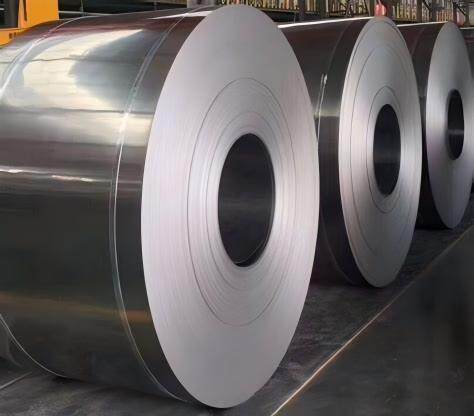

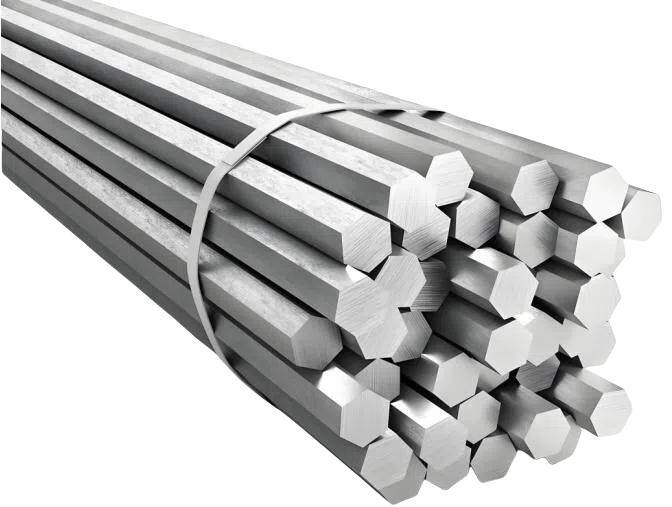

Product Forms Available

Bars, Plates, Pipes, Strips

Forgings: Rings, shafts, discs, customized shapes

Custom Machined Parts: According to drawings and specifications

Heat Treatment & Surface Finishing: Anodizing, sandblasting, precision polishing, coating, and other treatments

Applications

Aerospace & Aviation: Airframes, engine parts, landing gear

Medical: Implants, prosthetics, surgical tools

Chemical Industry: Heat exchangers, reactors, piping

Marine: Ship parts, propeller shafts, desalination systems

Energy: Turbine blades, nuclear components, fuel cells

Automotive & Industrial: Engine valves, exhausts, lightweight parts

Why Choose Us

Support for both small-batch customization and bulk supply

Full-process services including forging, machining, and heat treatment

Drawing-based production with support for third-party inspection and certification

Fast export handling with full support for international logistics and customs clearance

Contact us for tailored solutions and competitive offers!

- +86 15802938984

- shanghaiwtinternational@gmail.com