1J22Q is a newly developed material optimized and improved on the basis of traditional 1J22 soft magnetic alloy. It not only retains the core advantage of 1J22 alloy with high saturation magnetic induction, but also achieves significant improvement in mechanical properties.

Compared with ordinary 1J22, 1J22Q has higher mechanical strength, effectively reducing the risk of fracture of motor laminations during punching and assembly, and is particularly suitable for high-speed and high-rotation motor applications.

Key Properties & Advantages

Enhanced magnetic performance: all indicators exceed Chinese Standard GB/T 14986.3-2018

Higher mechanical strength: significantly improves rotor lamination structural strength

Improved reliability: reduces fracture risk and extends motor service life

High-speed adaptability: suitable for high-speed rotation, ensuring motor stability

Typical Applications

Aerospace motors

High-speed railway traction motors

High-performance servo motors and generators

Special electromagnetic devices

Mechanical Properties (Strip 0.2mm)

Tensile strength Rm ≈ 800MPa

Yield strength Rel0.2 ≈ 350MPa

Elongation A ≈ 8%

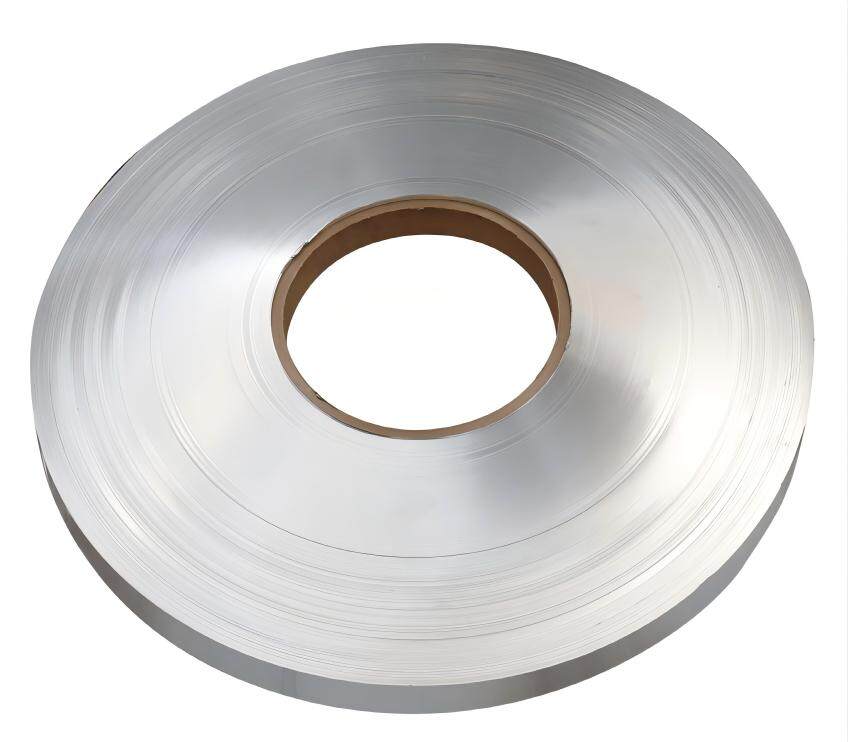

Supply Forms

Specification: strip

Condition: cold-rolled, annealed

Customization: available upon request

Standards: specifications available according to Russian, American, British, French, and Japanese standards

- +86 15802938984

- shanghaiwtinternational@gmail.com