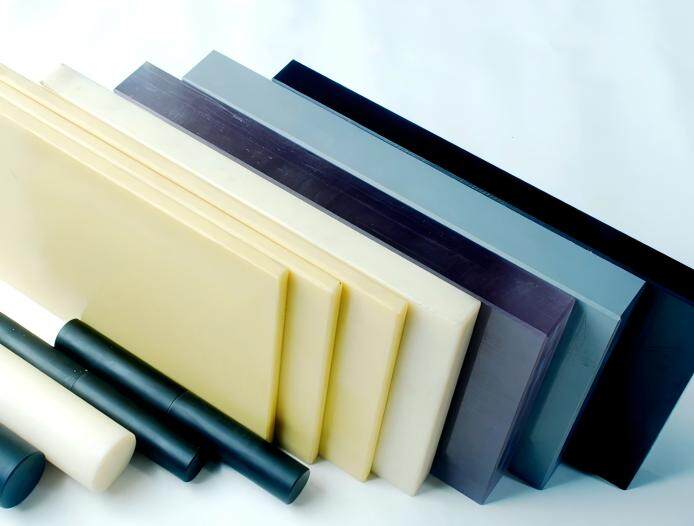

Product Types & Customization Range

Insulation Rods

Diameter range: 6mm-200mm

Customizable length

End-face machining, cutting, and drilling available

Applications: Motor bearing supports, precision insulation columns, mechanical support components

Insulation Tubes

Inner diameter, outer diameter, and wall thickness customizable

Available in molded or pultruded forms

Applications: High-voltage insulation sleeves, wire protection tubes, equipment shielding pipes

Product Advantages

High Mechanical Strength: Outstanding tensile, compressive, and flexural performance

Superior Electrical Insulation: Excellent arc resistance, leakage resistance, and stable dielectric properties

High Dimensional Accuracy: Pultrusion process ensures uniform diameter and length

Heat & Corrosion Resistance: Long-term operating temperature up to 155℃; resistant to moisture and mild acids/alkalis

Flexible Customization: Custom diameters, lengths, and wall thicknesses available

Application Fields

Motors & Transformers: Insulation supports, bushings, end-cap insulation columns

Switchgear & Power Distribution Equipment: High-voltage insulation sleeves, wire protection tubes

Machinery & Industrial Equipment: Insulation shafts, precision insulating structural parts

Rail Transit & Energy: Electrical insulation components, wind power equipment insulation supports

- +86 15802938984

- shanghaiwtinternational@gmail.com