Stainless Steels – Durable, Corrosion-Resistant, and Versatile

Key Material Advantages

Excellent Corrosion Resistance: Resists rust and chemical attack in various environments including marine, acidic, and high-humidity conditions

High Mechanical Strength: Maintains toughness and fatigue resistance across a wide range of temperatures

Hygienic and Easy to Clean: Non-reactive with food, pharmaceuticals, and chemicals, ideal for sanitary and medical applications

Good Formability and Weldability: Suitable for stamping, bending, machining, and welding, maintaining consistent surface quality

Aesthetic Appeal: Offers a clean, modern appearance with various finishes (mirror, brushed, matte)

Common Grades

Austenitic Stainless Steels: 304 (S30400), 316 (S31600), 321 – Most widely used, combining outstanding corrosion resistance and excellent formability.

Ferritic Stainless Steels: 430, 409 – Cost-effective with good resistance to oxidation and stress corrosion cracking.

Martensitic Stainless Steels: 410, 420 – High hardness, strength, and wear resistance for industrial and tooling applications.

Duplex Stainless Steels: 2205, S31803 – Superior pitting resistance and high strength for harsh chemical and marine environments.

Precipitation-Hardening (PH) Grades: 17-4PH (S17400), 15-5PH – Heat-treatable stainless steels with high strength and excellent corrosion resistance.

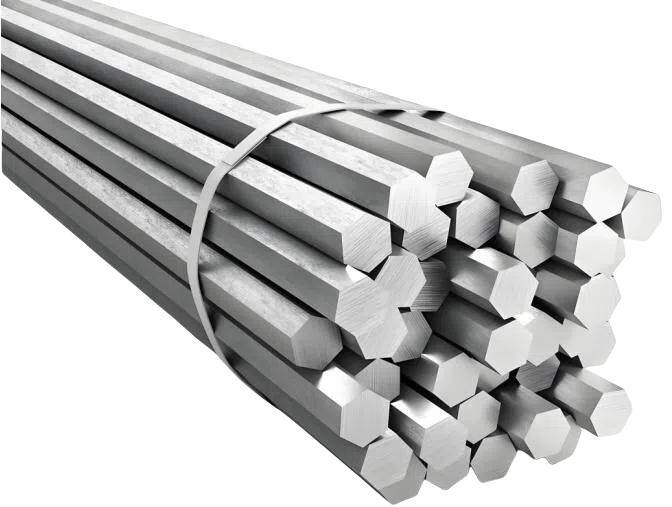

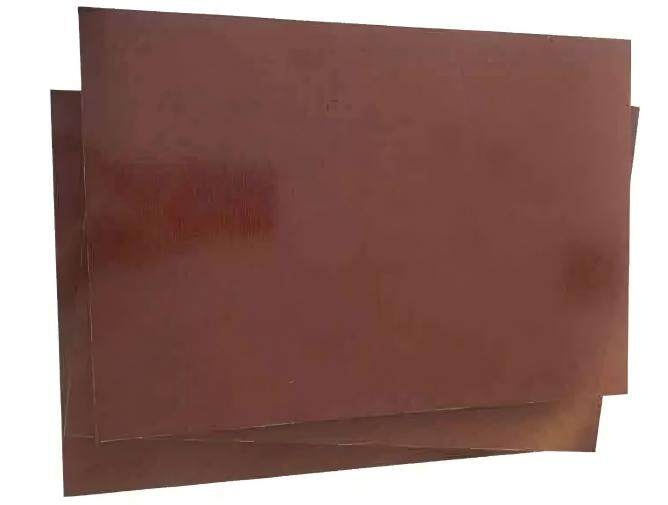

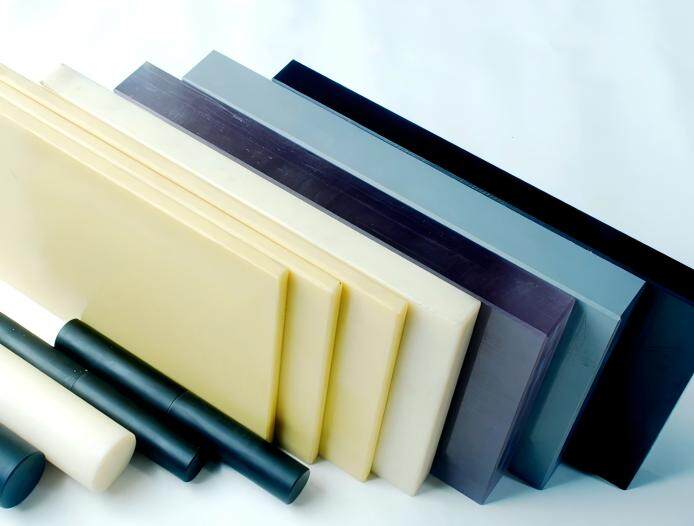

Product Forms Available

Bars, Plates, Pipes, Strips

Forgings: Rings, shafts, discs, customized shapes

Custom Machined Parts: According to drawings and specifications

Heat Treatment & Surface Finishing: Anodizing, sandblasting, precision polishing, coating, and other treatments

Applications

Construction & Architecture: Structural components, facades, handrails, fittings

Food & Pharmaceutical Equipment: Tanks, pipelines, sanitary equipment

Energy & Chemical Industry: Heat exchangers, pressure vessels, valves, pipelines

Automotive & Transportation: Exhaust systems, chassis, engine parts

Medical Equipment: Surgical instruments, implants, medical devices

Why Choose Us

Support for both small-batch customization and bulk supply

Full-process services including forging, machining, and heat treatment

Drawing-based production with support for third-party inspection and certification

Fast export handling with full support for international logistics and customs clearance

Contact us for tailored solutions and competitive offers!

- +86 15802938984

- shanghaiwtinternational@gmail.com